Description

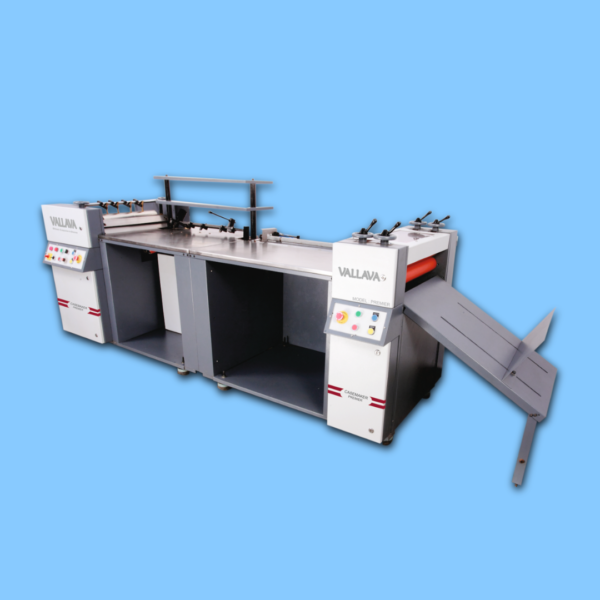

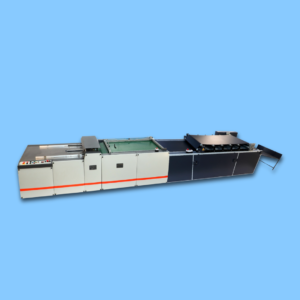

Economic High Quality Multi-Use Hard Case Binding Machine:

PREMIER model- is designed for variety of case binding jobs, demanded by modern market. This machine is made using rust resistant stainless steel glue rollers & working table for smooth & neat working the production capacity around 100 p/h.

Reliable and Proven gluing system

Gluing unit 20 inch in Premier and 40 inch in Premier Plus stainless steel glue rollers ensure proper and consistent glue application with high speed paper feeding system with one operator unit in premier and two operator unit In premier plus. Operator can operate the machine without touching the glue. Cartridge type glue tank with separate hot water tank is provided. Precise control of paper releasing tension blades is given for proper paper release and high speed run; thus the problem of paper being stuck in glue rollers is eliminated. This is maximum high speed paper feed system in this kind in the market at present.

High-Tech Pneumatic Turning System

Major difference in both the machine is single turning unit in premier and double turning units in Premier Plus model. Turning system is pneumatic in nature and does not have a pedal system. The operator can program the stroke timing by precision of seconds. This will be used for holding the necessary time of turning bar movement, to hold the glued maximum gsm paper, Rexene or cloth and turning-in to paste by proper manner. An adjustment is provided to process hard boards up to 6MM thickness with a unique locking system.

Unique Dust- Free Calendaring System

Four nos. of quality silicon rollers (2 upper and 2lower) are used which are easy to clean and provide proper pressure for removing air bubbles. Fine rollers control Knob-Cum- Locker is provided for constant disengagement of upper and lower calendaring rollers while running the job. This is to ensure that the case is free from glue and dust on front side especially when using costly wrappers like White papers, Wedding Card Products, Quality binding clothes etc., Inching and reverse forward facility given to set any thickness hard board and MDF boards from lmm to 6 mm and all four rollers engaged with hard and gears. Premier plus calendaring unit with conveyor system provided for both pneumatic turning unit operator for speed production. It is a major requirement of hard case binders today.